Hot Plate Soldering

All the articles on the web are true. It’s possible to do high-quality SMD soldering at home. And it’s easy.

First, acquire materials. Get a $14 hot plate and a $12 syringe of 63⁄37 solder paste. Then if you don’t have one already, get a multimeter with a temperature probe. Next, I recommend a roll of Kapton tape. And then finally, find some PCBs and surface- mount parts for practice.

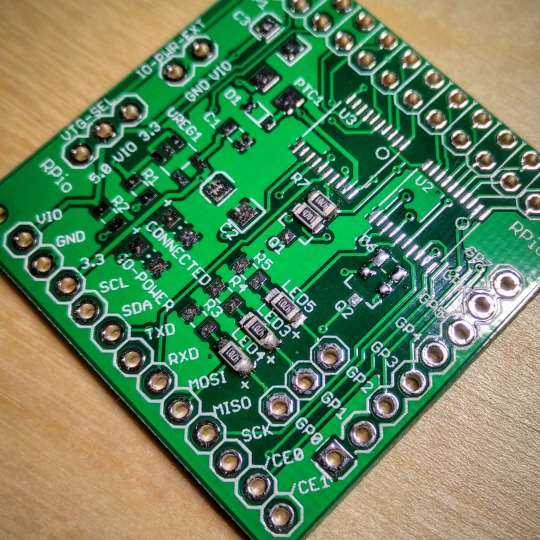

Now for the actual soldering. Squeeze a tiny bit of solder paste onto each pad on the PCB, then with some tweezers, place each SMT component where it belongs. I use a headband magnifier (2X, 10-inch) so I can see what’s going on. Don’t worry too much about getting the parts exactly straight; as long as they’re touching the paste, they’ll be good.

When you’re ready, tape the temperature probe onto one of the PCBs. If there’s no room, then use a scrap PCB. Turn on the multimeter and make sure it’s reading the temperature in Celsius. Set the PCBs on the hot plate. Turn the hot plate on to warm (the lowest setting). Watch the temperature go up. It should take maybe two minutes to get to around 160 degrees (again, that’s Celsius).

Now turn off the hot plate. The temperature should keep going up, and around 175 degrees (actually 183 for 63⁄37, but my probe was probably slightly raised off the PCB) you should see the solder paste suddenly turn shiny. Because you already turned off the hot plate, the rate of heating should slow down and then start going down. This is good.

Eventually the solder will become dull. By now you’ve burned yourself at least once, so you’ll remember to pick the PCBs up off the hot plate with the tweezers.

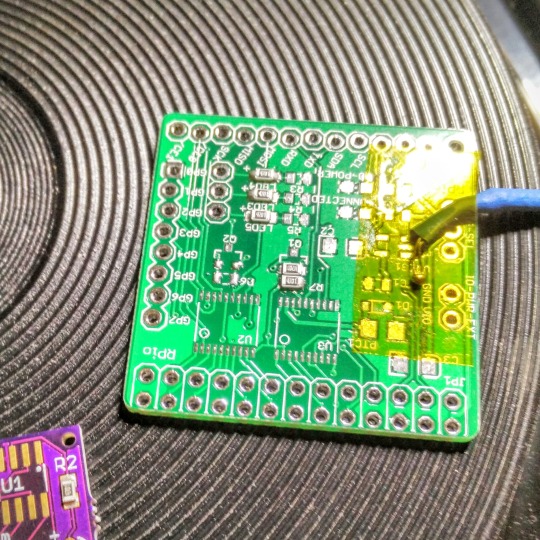

Examine with a magnifying glass or loupe. You will probably be very happy with the outcome.